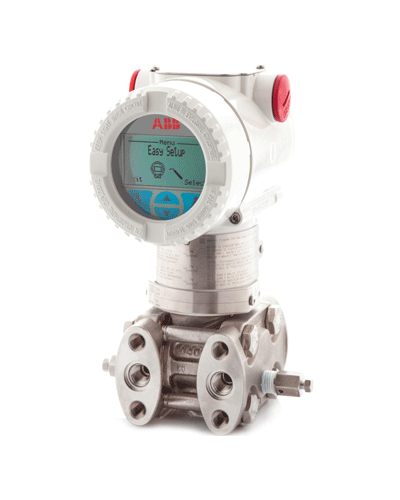

ABB 266DHH Differential Pressure Transmitter

(GST 18% Exclusive)

ABB 266DHH Differential Pressure Transmitter maximum working pressure of up to 5MPa (725psi). This pressure transmitter becomes the right solution for clean process fluids (generally water and clean oils). The pressure transmitter performance exceeds the expectations of direct-mounted diaphragm seal versions of differential pressure transmitters.

Applications: Domestic, Process engineering, Chemical industry, Petrochemical industry Applications.

Customers who bought this item also bought

-

₹12,084.00 – ₹13,984.00

(GST 18% Exclusive)

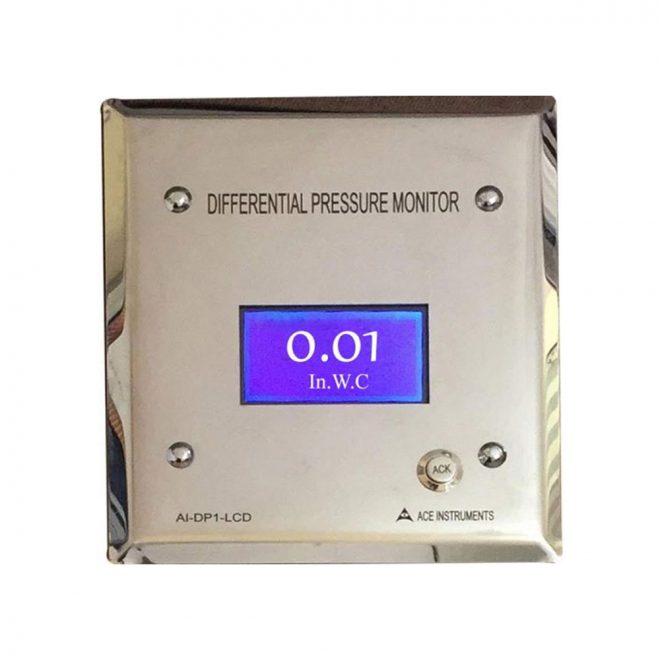

Ace AI-DP1-LCD Differential Pressure Indicator Transmitter

-

₹135,000.00

(GST 18% Exclusive)

ABB 266DSH Differential Pressure Transmitter

-

₹7,349.00 – ₹8,591.00

(GST 18% Exclusive)

ACE AI-DIGI-MAG-T Digital Differential Pressure Transmitter

-

₹7,349.00

(GST 18% Exclusive)

Ace AI-LPTX Differential Pressure Transmitter

ABB Differential Pressure Transmitter Model 266 is the first and only pressure transmitter with TTG (Through the Glass Keypad ) technology allowing full configuration with closed covers. In addition to the plug-in terminal block, this transmitter features an in-field replaceable electronics module that thanks to the auto-configuration functionality dramatically improves plant productivity. Its intuitive plug-and-play display with an easy setup menu provides configuration and zero trim in minutes helping customers in saving time and lowering maintenance and inventory costs. This certification is a real guarantee of protection and makes of 266DHH the smartest fit in Safety-critical loops.

Features of ABB Differential Pressure Transmitter :

- Base accuracy: from ±0.06%

- Span limits: 0.27 to 2400kPa; 1.08inH2O to 348psi

- Multiple protocol availability – provides integration with HART®, PROFIBUS PA, FOUNDATION Fieldbus, and WirelessHART platforms offering interchangeability and transmitter upgrade capabilities

- Full compliance with PED Category III

Additional information

| Weight | 1 kg |

|---|---|

| Manufacturer | ABB |

| Model No | 266DHH |

| Accuracy_1 | 0.06 % |

| Output | Two–wire 4 to 20 mA |

| Power Supply | Power Supply from 9 to 32 V DC |

| Integral Display | Wide screen LCD, 128 x 64 pixel, |

| Operating Temperature | -10 to +60 °C |

| Connections | on flanges : 1/4 – 18 NPT on process axis |

| Stability | ±0.15 % of URL over a ten years period |

| Current consumption | operating (quiescent): 15 mA fault current limiting: 20 mA max |

| Diaphragm Materila /Fill Fluid( Wetted Part ) | AISI 316 L ss (Silicone oil) |

| Output Interface | PROFIBUS PA communication according to Profibus |

| Process Flange | AISI 316 L ss (Horizontal connection) 1/4 – 18 NPT-f direct |

| Electromagnetic Field | Meets all the requirements of EN 61326 and NAMUR NE-21. |

| Supply voltage | Within voltage/load specified limits the total effect is less than 0.005 % of URL per volt. |

| Housing Material and Electrical Connections | Aluminium alloy |

| Integral LCD | Standard Digital LCD integral display |

| Bolts and nuts | AISI 316 ss bolts and nuts Class A4–50 per UNI 7323 |

| Warranty | 1 Year Manufacturing Warranty |

| Calibration | Standard: at maximum span, zero based range, ambient temperature and pressure; Optional: at specified range and ambient conditions. |

| Weight | 650 Grams |

Reviews

There are no reviews yet.