Precision matters: Discover the power of calibrators for accurate and reliable measurements in your industry

A calibrator is a device or a process tool used to ensure the consistency and accuracy or precision of another device or system.

Calibration is the process of adjusting or verifying the accuracy of a device or instrument by comparing its measurement values against a known standard. A calibrator is a device or tool used to perform this process.

In general, calibration is important because it ensures that instruments or devices are providing accurate and reliable results. This is particularly important in fields where precise measurements are essential, such as engineering, science, and manufacturing.

Calibrators are used to adjust or verify the accuracy of a wide range of instruments and devices, including pressure gauges, temperature sensors, flow meters, and electrical meters. Depending on the specific device being calibrated, the process may involve adjusting settings or making physical adjustments to the device.

To ensure accurate measurements, calibration is also important for compliance with regulations and industry standards. Many industries have specific requirements for calibration, and regular calibration may be necessary to maintain certification or meet regulatory requirements.

Why are calibrations required?

Calibrations are required to ensure that the measurements taken by an instrument or device are accurate and reliable. Over time, instruments can drift out of calibration due to wear and tear, changes in environmental conditions, or other factors. If an instrument is not calibrated regularly, it can produce incorrect measurements, which can have serious consequences in industries such as healthcare, aerospace, and manufacturing.

Calibrations are also required for compliance with industry regulations and standards. Many industries have specific requirements for calibration and require proof of calibration before an instrument can be used.

For example, In a pharmaceutical company, there may be a significant number of pressure gauges (100 or 200), and it is essential to ensure their accuracy is maintained. Calibration certificates are required to confirm the accuracy of the instruments and to identify if there is any drift in accuracy. This is where calibrators come in, which are used to compare and set the pressure gauges, as well as identify any offset issues.

By using calibrators to calibrate and correct the instruments, the pharmaceutical company can ensure that the pressure gauges are producing accurate and reliable measurements. This is crucial to ensure that the production process runs smoothly, as well as for regulatory compliance. Without proper calibration, inaccurate measurements can have serious consequences, including product quality issues and regulatory violations.

In addition to compliance and accuracy, calibrations can also be useful for improving efficiency and reducing costs. By ensuring that instruments are operating at peak performance, calibrations can help to minimize downtime, reduce waste, and improve overall productivity. Calibrations can also help to identify potential problems with instruments before they become serious, allowing for timely repairs or replacements.

Performing calibration

In many fields, precision is critical, and process instrumentation is necessary to monitor various variables. These instruments are used in manufacturing, laboratory work, and research and development, measuring variables such as humidity, conductivity, pressure, level, and flow. However, as there are so many variables, there are also many opportunities for instruments to produce incorrect readings.

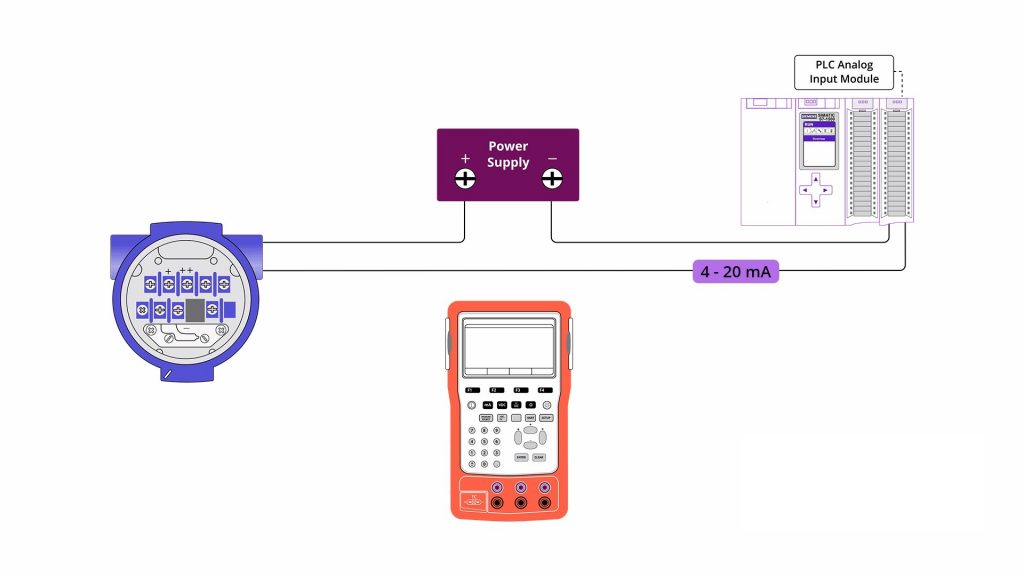

That’s where process calibrators come in as a vital tool. These instruments calibrate the readings of process instrumentation to ensure they are accurate. Without process calibrators, there would be no standard in process instrumentation, and the results produced by these instruments would not be reliable. Thus, process calibrators are critical to ensure that the data generated by process instrumentation is consistent and trustworthy across the world.

In the process of calibration, there is a master instrument that serves as a reference, and there is a calibrator responsible for performing the calibration procedure. The unit under calibration (UUC) is the device being calibrated. The purpose of using the master instrument is to compare its known accuracy against the UUC and determine any deviations or drift in accuracy.

By comparing the readings of the master instrument with those of the UUC, we can assess the level of drift or variation in the UUC’s accuracy. This information is then recorded in a calibration certificate to provide a comprehensive report of the calibration results.

The master device is used as a reference to evaluate the accuracy of the UUC. Any deviations or drift in the UUC’s measurements are noted and recorded in the calibration certificate for documentation and presentation.

A Pressure and Vacuum Calibrator is a specialized device used to generate precise pressure levels for calibrating pressure instruments. It operates on a comparison method, where the pressure instruments under calibration (UUC) are compared against a highly accurate master instrument.

During the calibration process, the pressure instruments are adjusted and evaluated by comparing their readings to those of the master instrument. This allows for the identification and correction of any discrepancies in accuracy. By using the master instrument as a reference, the calibration procedure becomes more efficient, reducing the time required to calibrate the pressure instruments.

The primary goal of reference calibration is to minimize the calibration time while ensuring the accuracy of the pressure instruments. The comparison method provides a reliable and effective approach to calibrating the instruments, guaranteeing their proper functioning and adherence to specified standards. At Instrukart, these calibrator Products can be suggested to the required consumers.

For more expertise please reach www.instrukart.com or mail us on info@instrukart.com